SPECIALTY - MACHINERY - TOOLING - SERVICES

SPECIALTY MACHINERY

With one of the most comprehensive and up to date ranges of machinery in New Zealand, we have the ability to recondition engines anywhere from performance motorcycles to heavy diesel, from start to finish.

-

![]()

RMC CNC V80

The RMC V80 is a true simultaneous 3 axis, PC based CNC controlled machining centre. We have also had a 4th axis enabled. Our machine is big enough to do all but the very biggest of motors in New Zealand. It is also capable of machining very small jobs & also conventional CNC milling jobs. The computer employs a simple conversational menu driven programming, which minimizes human error. It also uses conventional "G" coding capabilities, this enables programing of unusual jobs by our technicians.

-

![]()

Crankshaft Grinder

We grind crankshafts from small motorcycles to large diesel industrial. Our qualified technicians guarantee precise accuracy with electronic auto-sizing on our versatile crankshaft grinder.

-

![]()

Surface Grinder

With the new Berco STC461 we have the latest in surface grinding technology. This machine allows us to grind and mill the largest automotive/industrial cylinder blocks and heads, delivering the highest quality surface finishes available, with speed and accuracy.

-

![]()

Lathe

We have a range of lathes onsite that we use for alteration and fabrication of parts.

-

![]()

Cylinder Head Shop

The Serdi 4.0 Cylinder Head Shop has the latest tooling including CBN T.R.I system for cutting ease on even the hardest of heavy diesel seats. Fully kitted with valve guide range from 4-16mm and seat range from 14mm high performance motorcycle to 60mm heavy diesel. The Serdi provides the speed and accuracy needed for precise engine reconditioning.

-

![]()

Custom Cracktesting Bay

We provide magnetic particle testing, which is the highest sensitivity test for the detection of surface cracks. Crankshafts, camshafts, cylinder heads, axles, gears and many other types of ferrous components can be thoroughly checked by this method. We also provide dye penetrant testing.

-

![]()

Sunnen Digital Balancer

One of the only 2 in New Zealand & capable of balancing assemblies up to 1000lbs in weight. The Sunnen DCB-200 digitally controlled balancing machine is fast, accurate and extremely precise, eliminating any guess work. The DCB-2000 employs a PC control with Windows based software for enhanced setup & operating versatility, capable of meeting requirements for Nascar & V8 Supercars. Precisely balanced crank assembly essential for overall performance & longevity.

-

![]()

Sunnen CV 616 Hone

Our Sunnen CV 616 Hone delivers an unsurpassed surface finish and allows us to hone to OEM specifications as recommended by Cat & other leading manufacturers. This hone is a very versatile and accurate machine for all automotive, industrial & marine applications.

-

![]()

Sunnen VGS-20 Valve Guide & Seat Machine

The VGS-20 can handle everything from subcompacts up to large 1220mm diesel cylinder heads. This machine can install and ream quickly and accurately, and drill and tap for screw in studs & removal of broken exhaust studs.

To complement the machine, we also have the following tooling:

• Single-blade, three angle seat cutting kit

• Valve seat pocket cutter kit

• Single blade three angle seat cutting kit

• Three blade three angle seat cutting kit

-

![]()

Purpose Built Cleaning Bay

Complete with hot acid tank for the decarbonisation of large iron block & cylinder heads and a cold acid tank for aluminium cylinder heads & paint removal.

A rotating hot water washing machine for cleaning/degreasing of automotive & mechanical parts, which is suitable for ferrous & non-ferrous metals.

Our cleaning bay has been purpose built with a closed drainage system that ensures all chemicals are disposed of correctly, protecting the environment.

SPECIALTY TOOLING

We have an extensive range of specialty tooling available here at Henson and Murray. With the latest tooling we are able to precisely and accurately complete even some of the most complex jobs.

-

![]()

RMC Tool Presetter

The Precision of Our Digital Optical Laser Presetter

At Henson & Murray Engine Rebuilders, precision is at the core of our machining process. Our presetter, a state-of-the-art digital optical laser magnifier, projects the tool to be set onto a digital screen with astonishing accuracy, down to the 5th decimal point. This level of precision ensures that our tools are perfectly aligned and ready for the most demanding machining tasks.

-

![]()

Mira Counter Bore Tool

Portable Counter Boring Tool for Off-Site Excellence

At Henson & Murray Engine Rebuilders, we pride ourselves on our versatility and commitment to quality, even when working off-site. Our portable counter boring tool is a testament to this dedication. This advanced tool allows us to machine liner recesses to the highest standard, no matter where the job takes us.

-

![]()

Cummins Injector Tube Tooling

Injector Seat Tooling for Cummins Signature ISX, E5, and X15

We offer specialized injector seat tooling for the latest Cummins Signature ISX, E5, and X15 engines. This tooling ensures precise installation and optimal performance of stainless injector tubes.

Precision Tooling: Accurate installation for a perfect fit.

High-Quality Materials: Durable and long-lasting performance.

Compatibility: Designed specifically for Cummins engines.

Trust Henson & Murray Engine Rebuilders for precise and reliable engine component installations.

-

![]()

Cummins Injector Tube Tooling

Injector Seat Tooling for Cummins 855 Small & Big Cam

We offer specialized injector seat tooling for the Cummins 855 Small & Big Cam engines. This tooling ensures precise installation and optimal performance of stainless injector tubes.

Precision Tooling: Accurate installation for a perfect fit.

High-Quality Materials: Durable and long-lasting performance.

Compatibility: Designed specifically for Cummins 855 engines.

Trust Henson & Murray Engine Rebuilders for precise and reliable engine component installations.

-

![]()

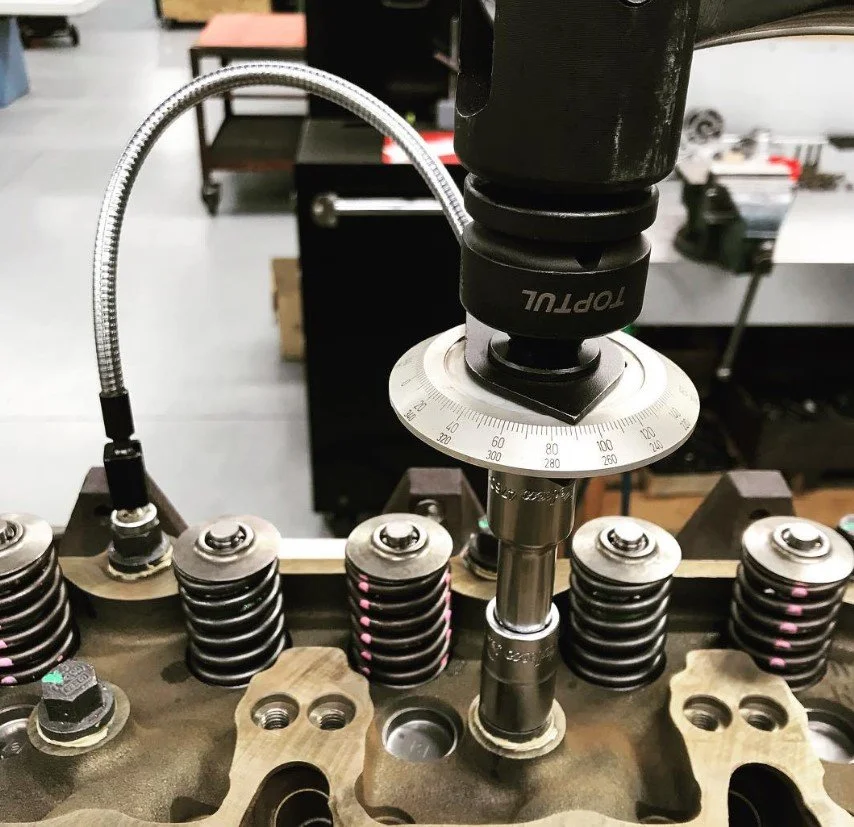

Spring Pressure Tester

Fast, Accurate, and Repeatable Valve Spring Testing

At Henson & Murray Engine Rebuilders, we ensure quick, precise, and consistent testing for all automotive, diesel, and race valve springs. Our advanced equipment guarantees each spring meets the highest performance standards, providing reliability and optimal engine performance.

-

![]()

Hardness Tester

Accurate Testing of Engine Steels

At Henson & Murray Engine Rebuilders, we excel in precise testing of steels, whether it's for overheated aluminum cylinder heads or crank journal conditions in heavy diesel engines.

Overheated Aluminum Cylinder Heads:

Hardness Testing: Determine salvageability.

Repair: Straightening and restoring integrity.

Crank Journals in Heavy Diesel Engines:

Dial Indicator Testing: Check roundness and taper.

Failure Analysis: Identify root causes and ensure effective repairs.

Our advanced techniques and state-of-the-art equipment guarantee accurate testing and reliable solutions..

-

![]()

GM LS Main Cap Removal/Puller

Having a GM LS Main Cap Puller offers several benefits:

Efficiency: Quickly and easily removes main bearing caps, saving time and effort.

Safety: Ensures caps are removed safely without prying, hammering, or damaging dowels.

Precision: Provides uniform pressure for even removal, preventing damage to the engine block.

Ease of Use: Simple, one-motion operation makes the task straightforward and hassle-free.

This tool is essential for anyone working on GM LS Series V8 engines, especially those with main studs.

-

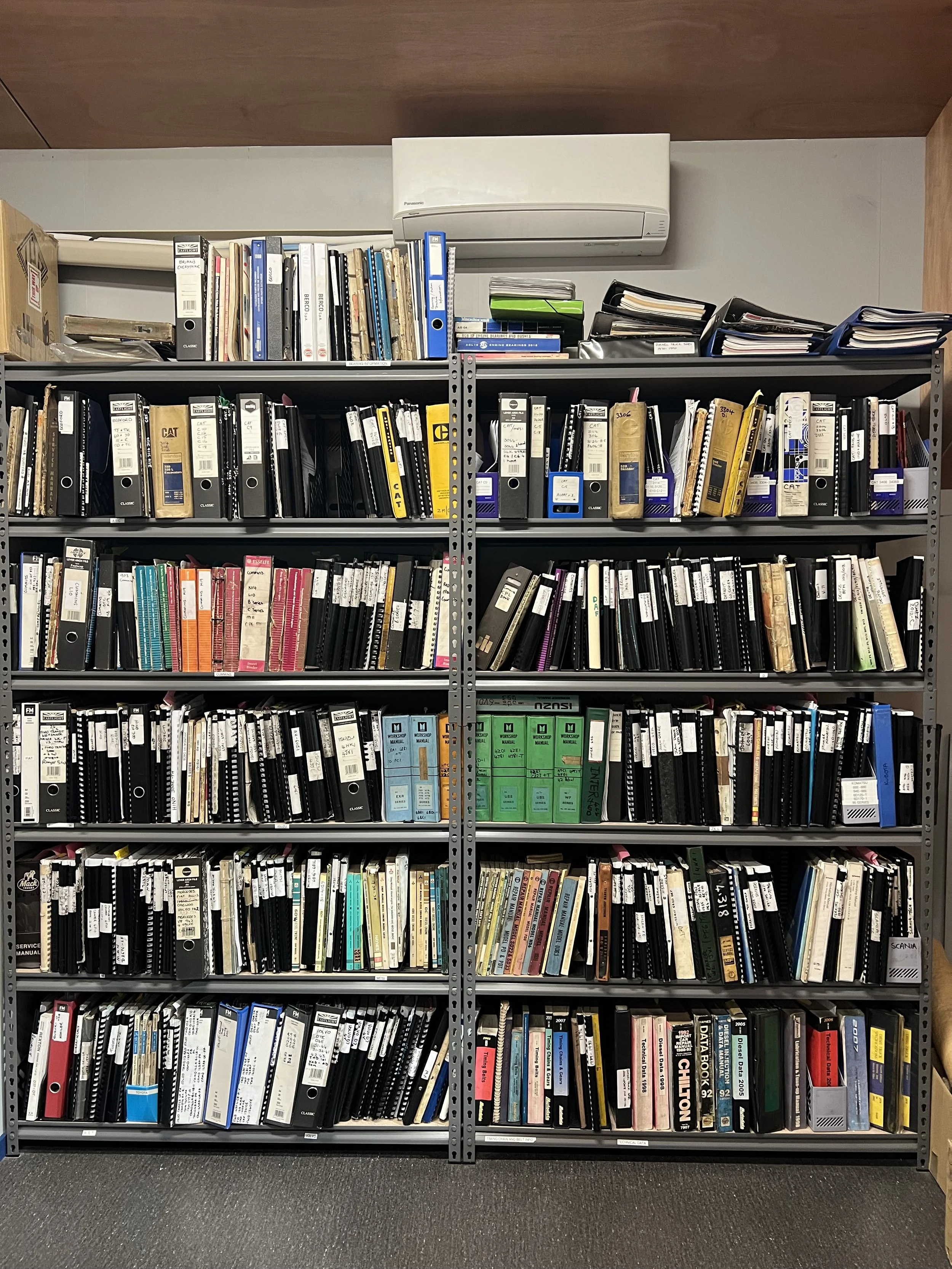

![Engine Manual Library]()

Engine Manual Library

The Value of Our Manuals

In today's digital age, having new manuals available online is incredibly convenient and accessible from anywhere. However, our collection of physical manuals still holds significant value.

At Henson & Murray Engine Rebuilders, we understand the importance of having multiple resources at your fingertips. That's why we maintain a robust library of both digital and physical manuals to support our comprehensive engine rebuilding services.

-

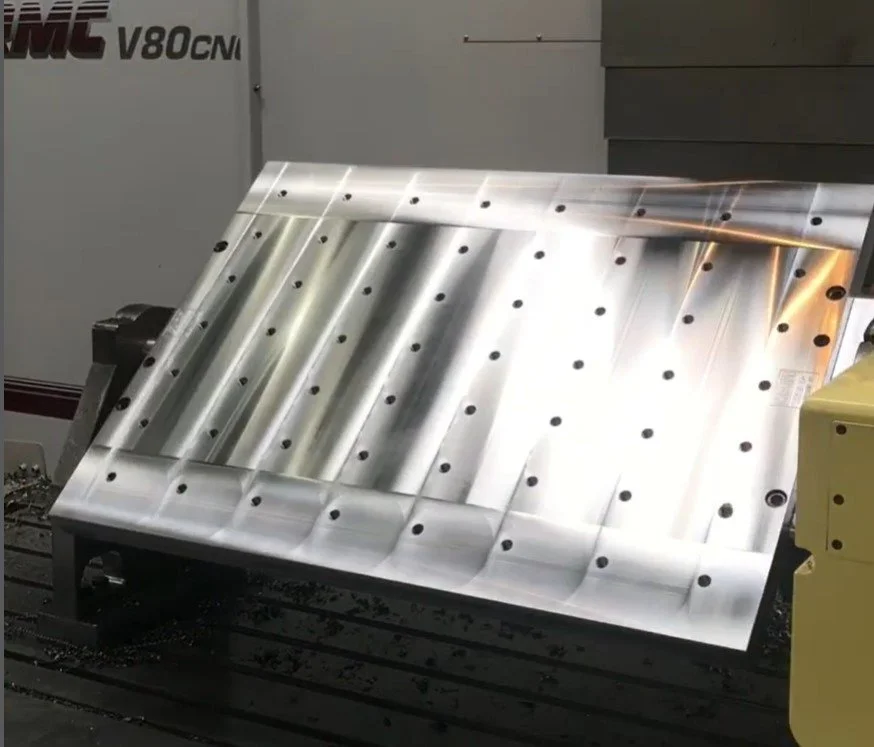

Torque Plates

Advantages of Having an Array of Torque Plates

Accurate Machining: Torque plates replicate the forces exerted by the cylinder head, ensuring precise machining and reducing distortion during assembly.

Improved Ring Sealing: Ensures better ring sealing, leading to improved engine performance and longevity.

Consistent Bore Quality: Provides uniform pressure, resulting in consistent bore quality and reduced cylinder taper.

Enhanced Reliability: Engines assembled with torque plates tend to wear more evenly and last longer.

-

![]()

Rotary Table Bed

Advantages of Using a Rotary Table Bed for Machining Engine Components

Enhanced Precision: Accurate positioning and rotation for tight tolerances.

Multi-Axis Machining: Complex cuts and operations on multiple axes in one setup.

Increased Efficiency: Reduces manual repositioning, leading to shorter lead times and higher productivity.

Versatility: Handles tasks like drilling, milling, and honing.

Improved Product Quality: Higher-quality components with better performance and longevity.

-

![]() Description goes here

Description goes here

SPECIALTY SERVICES

Over the years we have adapted to the industry and have numerous Specialty Services available

-

Closed decked blocks

Description goes here -

![]()

Crack Repair Inserts

Crack Repair Inserts for Engine Components

At Henson & Murray Engine Rebuilders, we restore the integrity of cracked engine components, such as cylinder heads or engine blocks, using crack repair inserts.

Effectively repairing the crack, ensuring the longevity and reliability of your engine components.

-

Lifter Bore Sleeves

Description goes here -

Refaceing CAT C16 Saddles

Description goes here -

Cat C15 Rocker Shaft Troughs

Description goes here -

Cummins QSX & ISX Damper Hub & Timing Gear Removal

Description goes here -

![]()

Blueprint Programs

Have a look at the video posted to our Instagram page:

A time lapse of setting up a Ford 4.6 getting ready for blueprinting - probing centerline of crank, front dowel, sump rail, bores and decks.

-

![]()

Upper Counterbore Repair Sleeves

Utilizing our dedicated CNC machine, we ensure precise and durable repairs to maintain the integrity of the engine block by fitting new repair sleeves.

-

![]()

Fire Ring Grooves

We specialize in precision machining of fire ring grooves. Utilizing our in-house made tool holder, we ensure fast and accurate machining. By using probe centers based on manufacturers' dimensions, we achieve exceptional accuracy and efficiency in every project.

-

![]()

Torque Plate Honing

Why Use a Torque Plate for Honing?

1. Simulates Real-World Conditions:

Replicates Stress and Distortion: Ensures the cylinders are honed in the exact shape they’ll be under operating conditions.

2. Ensures Round and True Cylinder Bores:

Optimal Engine Performance: Leads to better combustion, improved power, and overall engine efficiency.

3. Enhances Engine Longevity:

Reduces Wear and Tear: Extends the life of the engine by minimizing wear on pistons and rings.

4. Guarantees Consistency:

Uniform Results: Provides consistent performance across the entire engine.

Using a torque plate during honing ensures precision, performance, and longevity for your engine.

-

![]()

Deepening O-Ring Grooves

Deepening the O-Ring Grooves on the Scania 9 Block: Take a look at the process.

At Henson & Murray Engine Rebuilders, deepening the o-ring grooves on the Scania 9 block after refacing the deck is crucial. This step ensures the correct crush is applied to the o-rings, guaranteeing a proper seal and preventing leaks. By adjusting the groove depth, we maintain engine performance and reliability.

This meticulous process underscores our commitment to precision and quality.

-

![]()

Thread Repair Inserts

In-House Thread Repair Inserts

At Henson & Murray Engine Rebuilders, we manufacture, machine, and install thread repair inserts in-house. These Edelbrock Shaver heads from a supercharged methanol-injected Chev 410ci struggled with the high revs and spring pressure during the race season. Our inserts not only repair the threads but also make them stronger than the original.

Trust Henson & Murray Engine Rebuilders to enhance your engine components with our high-quality thread repair inserts.